当前位置:

[辽宁]鹿程国际贸易有限公司

辽宁当地产品频道

电工钢硅钢片-新能源电工钢好品质用的放心

发布时间:2024-09-19 11:21:19 浏览次数:2 公司名称:[辽宁]鹿程国际贸易有限公司

以下是:电工钢硅钢片-新能源电工钢好品质用的放心的产品参数

| 最小起订 | 1 |

|---|---|

| 质量等级 | 精品 |

| 是否厂家 | 是 |

| 产品材质 | 冷轧 |

| 产品品牌 | 宝武日本进口 |

| 产品规格 | 0.08-0.65 |

| 发货城市 | 上海武汉 |

| 产品产地 | 上海武汉 |

| 加工定制 | 粗加工 |

| 产品型号 | 多种 |

| 可售卖地 | 全国 |

| 质保时间 | 一年 |

| 适用领域 | 电器马达电机变压器磁感器互感器稳压器继电器电磁开关新能源电机电动汽车变压器军工电机发电机组航天造船汽车等 |

| 是否进口 | 否 |

| 品名 | 电工钢 冷轧无取向电工钢 冷轧取向电工钢卷冷轧取向硅钢 取向电工钢冷轧无取向硅钢冷轧无取向硅钢 |

| 规格 | 0.08 0.1 0.05 0.18 0.2 0.23 0.27 0.3 0.35 0.5 0.65 1.0mm |

| 包装 | 原厂精包装 |

| 用途 | 电器马达电机变压器磁感器互感器稳压器继电器电磁开关新能源电机电动汽车变压器军工电机发电机组航天造船汽车等 |

以下是:电工钢硅钢片-新能源电工钢好品质用的放心的图文视频

电工钢硅钢片-新能源电工钢好品质用的放心,辽宁省鹿程国际贸易有限公司为您提供电工钢硅钢片-新能源电工钢好品质用的放心,联系人:鹿丙伟,电话:021-56152236、13764370568,QQ:871956683,请联系辽宁省鹿程国际贸易有限公司,发货地:宝山区蕰川公路777号宝钢厂区607-609室发货到辽宁省 沈阳市、大连市、鞍山市、抚顺市、本溪市、丹东市、锦州市、营口市、阜新市、辽阳市、盘锦市、铁岭市、朝阳市、葫芦岛市。 辽宁省 2022年,辽宁省实现地区生产总值28975.1亿元,按可比价格计算,比上年增长2.1%。

不容错过的电工钢硅钢片-新能源电工钢好品质用的放心视频展示!产品特点一目了然,为您的购买决策提供坚实依据。

以下是:电工钢硅钢片-新能源电工钢好品质用的放心的图文介绍

辽宁鹿程国际贸易有限公司位于宝山区蕰川公路777号宝钢厂区607-609室,优良的地理环境,现代化的产业集群,让企业具备了快速发展的基本动力。配套设施齐全。我司一路坚持用科技和信念打造过硬的产品和质量,在消费者心目中形成良好的口碑效应。成绩属于过去,奋斗属于未来。辽宁鹿程国际贸易有限公司秉承:德、孝、诚、爱和利他精神的企业理念,“创品质,树精品企业”的宗旨,“诚信、创新、发展”的经营理念,“用心服务、尽善尽美”的服务理念。

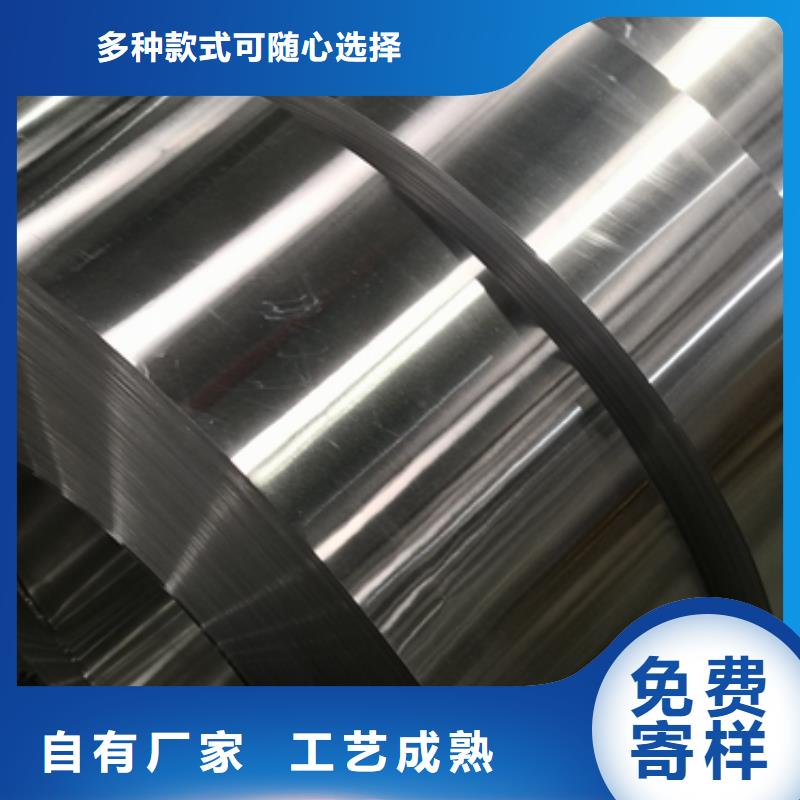

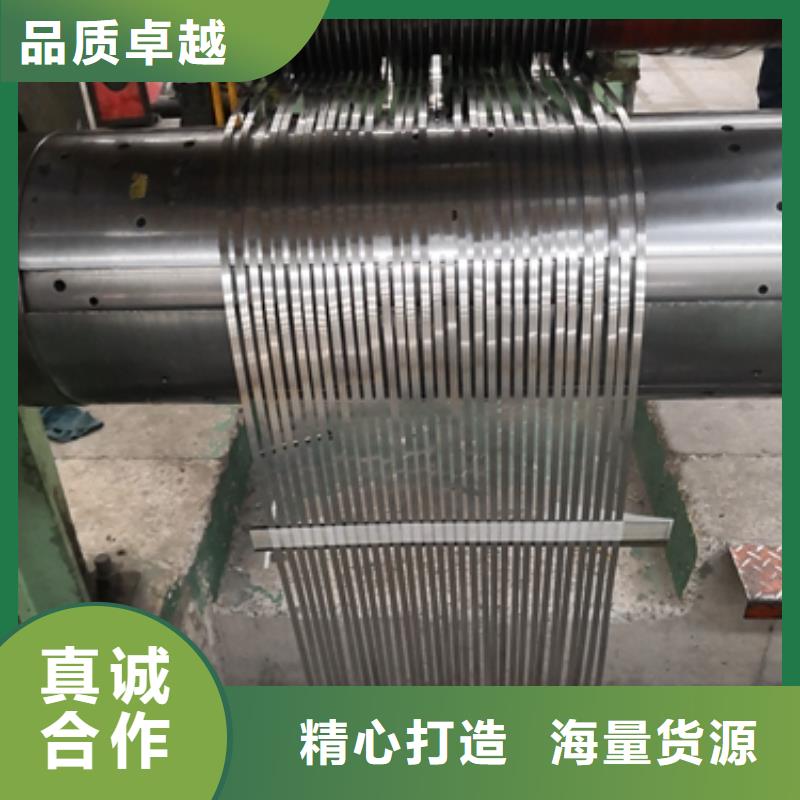

电工钢硅钢片硅钢是一种硅铁合金。用硅钢轧制的片材是电工领域中应用广的软磁材料,因而硅钢片又称电工钢片。硅钢片广泛用于电动机、发电机、变压器、扼流圈、电磁机构、继电器及测量仪表中电机工业大量使用厚度为0.35~0.50mm的硅钢片,用于:中型旋转机,压缩电机,通用马达,小型精密电机,电动汽车,压缩机,通用电机,电源变压器,精密变压器,节能电机,焊机变压器,稳压器,磁性密封器,加速器用电磁铁,汽车电机等;在电信高频技术中常用0.05~0.20mm的薄带钢片,以便更有效地降低涡流损耗。热轧硅钢片厚度为0.35~0.50mm,密度为7.55~7.70g/cm3,多用于大、中、小型交、直流电动机;冷轧无取向硅钢片厚度为0.35~0.50mm,密度为7.65~7.75g/cm3,多用于大型交流发电机、电动机,大、中、小型交、直流电动机;冷轧取向硅钢片厚度为0.23mm 0.27mm 0.3mm 0.35mm,密度为7.65g/cm3,多用于电力变压器、油浸式变压器,干式变压器,电抗器、磁放大器等;冷轧取向薄带厚度为0.05~0.20mm,多用于无线电高频变压器。

辽宁鹿程国际贸易有限公司技术力量雄厚,在新环境下适应了市场经济环境,充满了活力和创造力。公司坚持 汽车钢质量为上、保证信誉和尊重用户的服务宗旨,发扬自强不息、拼搏不止、求实自爱和志在上等的企业精神,竭诚为广大用户服务。

电工钢硅钢片In addition to the types listed above, there are also some special purpose electrical steel plates, such as 0.15 and 0.20mm thick 3% Si cold-rolled non oriented silicon steel strips and 0.025, 0.05, and 0.1mm thick 3% Si cold-rolled oriented silicon steel strips, used for medium and high-frequency motors, transformers, and pulse transformers; 0.7mm thick 3% Si high-strength cold-rolled non oriented silicon steel plate for relays and power switches; High strength cold-rolled electrical steel plate for new high-speed motor rotors; Low carbon electrical steel hot-rolled thick and cold-rolled plates for magnetic shielding and high-energy accelerator electromagnets such as medical magnetic resonance tomography scanners; 4.5% to 6.5% Si high silicon steel plates for high-frequency motors, transformers, and magnetic shielding.Generally, motors, transformers, and other electrical components are required to have high efficiency, low power consumption, small size, and light weight. Electrical steel plates are usually guaranteed to have magnetic properties based on core loss and magnetic induction strength [1] [2]. The requirements for the performance of electrical steel plates are as follows:Low core loss (PT)Iron core loss refers to the ineffective electrical energy consumed by an iron core when magnetized in an alternating magnetic field of ≥ 50Hz, abbreviated as iron loss, also known as alternating loss, and its unit is W/kg. The ineffective electrical energy consumed due to various obstacles caused by magnetic flux changes not only loses electrical energy through the heating of the iron core, but also causes temperature rise of the motor and transformer. The iron loss (PT) of electrical steel includes three parts: hysteresis loss, eddy current loss (Pe), and anomalous loss (Pa). Electrical steel plates have low iron loss, which can save a lot of electricity, prolong the operating time of motors and transformers, and simplify cooling devices. Due to the iron loss of electrical steel plates, which accounts for 2.5% to 4.5% of the annual electricity generation in various countries, countries always try their best to reduce iron loss in the production of electrical steel plates, and use iron loss as the most important indicator to assess the magnetic properties of products. The iron loss value of products is used as the basis for classifying product grades. Cold rolled oriented electrical steel: Cold rolled oriented electrical steel is a high-end product in the field of electrical steel. Compared with cold rolled non oriented electrical steel, its magnetism has strong directionality; It has superior high magnetic permeability and low loss characteristics in the direction of easy magnetization rolling. The iron loss of oriented steel strip in the rolling direction is only 1/3 of that in the transverse direction, and the ratio of magnetic permeability is 6:1. Application: The main purpose of cold-rolled oriented silicon steel strip is for transformer manufacturing.Full process cold rolled non oriented silicon steel coating: The surface of the full process cold rolled silicon steel is coated with a semi transparent insulation coating, which has different codes in different standards. Taking Baosteel‘s Q/BQB 480 2014 as an example:

电工钢硅钢片宝钢新能源汽车驱动电机用无取向电工钢EVI:宝钢为新能源汽车驱动电机用户提供从设计选材到产品量产的技术支持 电机设计选材支持,实现卓越的性能和成本控制; 铁芯用材和结构优化,实现性能或技术降本;铁芯加工制造支持,实现材料与装备 匹配; 新产品、当地新技术的应用,新能源汽车的竞争力。新能源汽车驱动电机用无取向电工钢产品体系:永磁同步电机是新能源汽车发展主流趋势,具有率、当地高转矩、当地高性以及小体积等优点。宝钢产品具有低铁损、当地高磁感和高强度的特点,满足各类电机设计和制造需求。普通系列:具有低铁损、当地高强度特点; 系列:具有低铁损、当地高磁感特点;高强度系列:磁感、当地铁损、当地强度三者综合性能优异; 高磁感系列:更高的磁感,满足高转矩、当地电机小型化的需求; 高强度系列:高强度,应用于高转速或超高转速转子。公称厚度为 0.15mm、当地0.20mm、当地0.25mm、当地0.27mm、当地0.30mm 和0.35mm 全工艺冷轧中频无取向电工钢带的术语和定义、当地分类和代号、当地一般要求、技术要求、检验和试验、包装、标志及检验文件等要求。本文件适用于宝山钢铁股份有限公司生产的、用于频率在

电工钢硅钢片-新能源电工钢好品质用的放心,辽宁省鹿程国际贸易有限公司为您提供电工钢硅钢片-新能源电工钢好品质用的放心产品案例,联系人:鹿丙伟,电话:021-56152236、13764370568,QQ:871956683,发货地:宝山区蕰川公路777号宝钢厂区607-609室。